How to apply and use the ANDON system?

What is an ANDON system?

It is a light signal that reveals anomalies on production lines so that they can be corrected as quickly as possible. This system is therefore developed for workers in the workshop.

The ANDON system was born in the Toyota company, it is part of a LEAN approach and more specifically of continuous improvement and Visual Management.

This device aims to improve the quality of work, allowing workers to optimise the manufacturing process.

This system is linked to the Jidoka method, which allows the various problems linked to production errors to be highlighted. Other methods such as Poka-Yoke, JIT, Takt-Time or Heijunka can be added to this system.

The ANDON is composed of three colours, each of which symbolises the state of the machines, the parts, or the progress of the production.

When to use the ANDON system?

This device can and should be used daily. Although it is an alarm signal, it should not be used only in extreme emergencies.

In most cases, workers will “pull the alarm” and ask for assistance.

What are the benefits of ANDON?

- Ongoing and immediate malfunction resolution.

This optimises the workers’ workstation.

- Saves time and improves quality.

Team leaders spend less time monitoring, which means they can focus more on anomalies.

- Improves process performance.

Anomalies are recorded, which makes it possible to know how often they occur and to share the information with all employees, to anticipate possible future anomalies and therefore the actions to be taken when problems arise.

Produces short, medium and long term machine performance statistics.

How to set up the ANDON system?

The different steps:

- Train employees in the ANDON system and therefore, if necessary, in LEAN methods.

- Define the main process steps and limits.

- Identify where the ANDON boards are to be placed, as they enable all the information from the production lines to be grouped together using the ANDON system.

- Define the right conditions for good functioning.

- Know when the system should display the colour green, orange or red.

- Identify any eventual problems and their impact on production and potential waste.

- Designing visual and audible alarms.

- Implementing temporary solutions to problems.

- In case of problems, implement temporary solutions such as setting up an alarm or signalling it with a bright colour (e.g., red).

- Think about the different alarms’ degree.

- Develop a recording and analysis process.

Why use ANDON?

This device allows the company to take another step towards the industry 4.0.

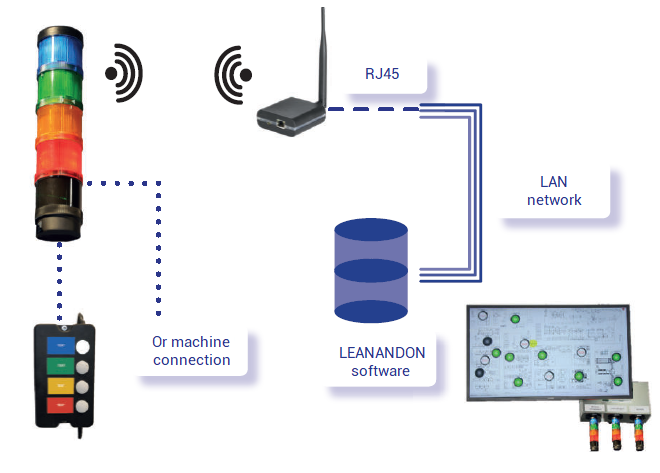

The ANDON system therefore makes it possible to optimise the manufacturing processes because it detects anomalies and forwards them directly to a table which is used by the managers. This system optimises the time taken to process anomalies and therefore reduces the impact on production when a problem occurs.

This method is at the heart of digitisation. It allows the digital technology use to be developed within the production workshops, tends to evolve towards collaborative work, and allows the factory’s different data to be grouped together. This system allows the computerisation of production monitoring, especially via software connected directly to the machines such as SESA-MES.

The ANDON system is also at the heart of Visual Management, so it enables the digital Visual Management to be developed with the different products inherent in this LEAN method.

Several tools can be used in addition to the ANDON system to study the data that has been collected. The information from ANDON can be displayed in the workshop to make the taking of anomalies into consideration easier.

To correctly use the data collected by the ANDON system, tools such as the E-LEANBOARD are used. This enables real-time communication with the teams on the production state in the workshop as well as the corrective actions to be taken.

Finally, the ANDON system makes it possible to integrate digital tools into production lines and thus improve communication between the production workshop and management.